Established the first manufacturing unit in Kolkata for cassettes and CDs with an initial capacity of 1.5 lakh units per month. Entered the Water Dispenser category in FY 2009–10.

Since 1989, we have been at the forefront of white-label and OEM manufacturing, helping brands bring high-quality cooling solutions to life with precision, reliability, and unmatched consistency.

With more than three decades of industry expertise, we’ve built a legacy rooted in trust and performance, strengthening the brands we partner with across markets and categories.

Our leadership in the Indian market is reflected in a 95% market share in water dispensers and a rapidly expanding footprint across refrigeration products, including chest freezers, mini bars, and vertical freezers.

As a true OEM partner, we deliver end-to-end support from concept and engineering to testing, certification, and manufacturing, backed by our in-house, NABL-certified Innovation Lab that ensures global quality, performance, and safety standards.

Years of OEM Excellence,

Built for Brands That Lead

Our Work Process

Research-Driven Ideation

1

Every Veeline product starts with market research, consumer insights, and real-world cooling challenges.

Precision Engineering & Manufacturing

2

Precision engineering and integrated manufacturing ensure design accuracy, quality control, consistency, and cost efficiency.

Multi-Stage Testing & Quality Validation

3

Each unit undergoes rigorous testing in NABL-approved labs following strict quality standards.

Streamlined Delivery & Dedicated Support

4

Our teams ensure seamless delivery, transparent coordination, and reliable support across all project requirements.

Our Journey

From our beginnings as a focused manufacturing enterprise to becoming a trusted OEM and white-label partner, Veeline has consistently prioritised quality, reliability, and engineering excellence. Every product line, facility expansion, and operational milestone reflects our commitment to precision manufacturing, continuous innovation, and long-term value creation for our partners.

1989

2011

Onboarded marquee customers Voltas and Blue Star. Began exports to the Middle East and North Africa (MENA) region, achieved CE/CB certifications, and started participating in global trade fairs including the Canton Fair.

2016

Expanded the product portfolio with RO Water Purifiers and commenced exports of Water Dispensers to France.

2019

2021

Established a dedicated North India facility for Chest Freezers, Visi Coolers, and Mini Bars. Expanded exports to Latin America and achieved the highest-ever Chest Freezer dispatches of 94,504 units in FY 2022–23.

2023

Became the first company to receive BIS certification for Water Dispensers. Expanded exports to North America withETL certification and crossed the milestone of serving 30+ countries globally. Achieved highest-ever production figures for Small Appliances (4,08,295 units) and Mini Bars (1,51,315 units) in FY 2024–25.

Veeline Industries was founded by Shri Anil Kumar Gupta, laying the foundation for a design-driven OEM/ODM manufacturing legacy.

2008 - 2009

Commissioned a state-of-the-art manufacturing facility in Nalagarh, Himachal Pradesh, strengthening Water Dispenser production capabilities.

2013

Set up a new Water Dispenser manufacturing unit near Surat port with an annual capacity of 2.4 lakh units. Recognized with the FIEO Top Exporter Award (2016–17) and secured SEDEX and EU certifications.

2018

Entered the Small Kitchen Appliances category at Nalagarh with blender manufacturing capacity of 6,00,000 units annually. Onboarded Wonderchef as a key customer.

2020

Veeline strengthened its customer portfolio by onboarding Daikin, marking a significant milestone that reinforced manufacturing credibility, expanded OEM partnerships, and demonstrated capability to meet quality and compliance standards.

2022

Showcased the complete product portfolio at the Canton Fair, unlocking new global opportunities. Achieved record production of 4,50,000 Water Dispensers in FY 2023–24.

2024

Where Smart Engineering Meets a Greener Future

Our products are designed with the future in mind - combining cutting-edge systems, energy-efficient technologies, and global quality standards. Veeline powers homes and businesses across continents while caring for the planet.

Our Factories

Leadership Team With Vision

Anil Gupta

Managing Director

Akshita Gupta

Anuradha Gupta

Suyash Borar

Aakriti Gupta

Abid Khuroo

Avinash Rogye

Esha Chakraborty

Sreenivasulu Matam

Why Choose Veeline

A product that has benchmark across multiple brands. Our flexible manufacturing processes let you customize multiple aspects of the final assembly to get you the perfect product that fits in.

Proven Expertise in Cooling Technology

Backed by decades of innovation, our cooling systems are engineered for precise temperature control, energy efficiency, and reliable performance across demanding commercial environments.

Built For Performance in Indian Conditions

Veeline’s freezers are engineered specifically for Indian climates, offering deep freezing even in high ambient temperatures, durable body structures, and advanced insulation for maximum cooling retention.

Nationwide Manufacturing & Global Standards

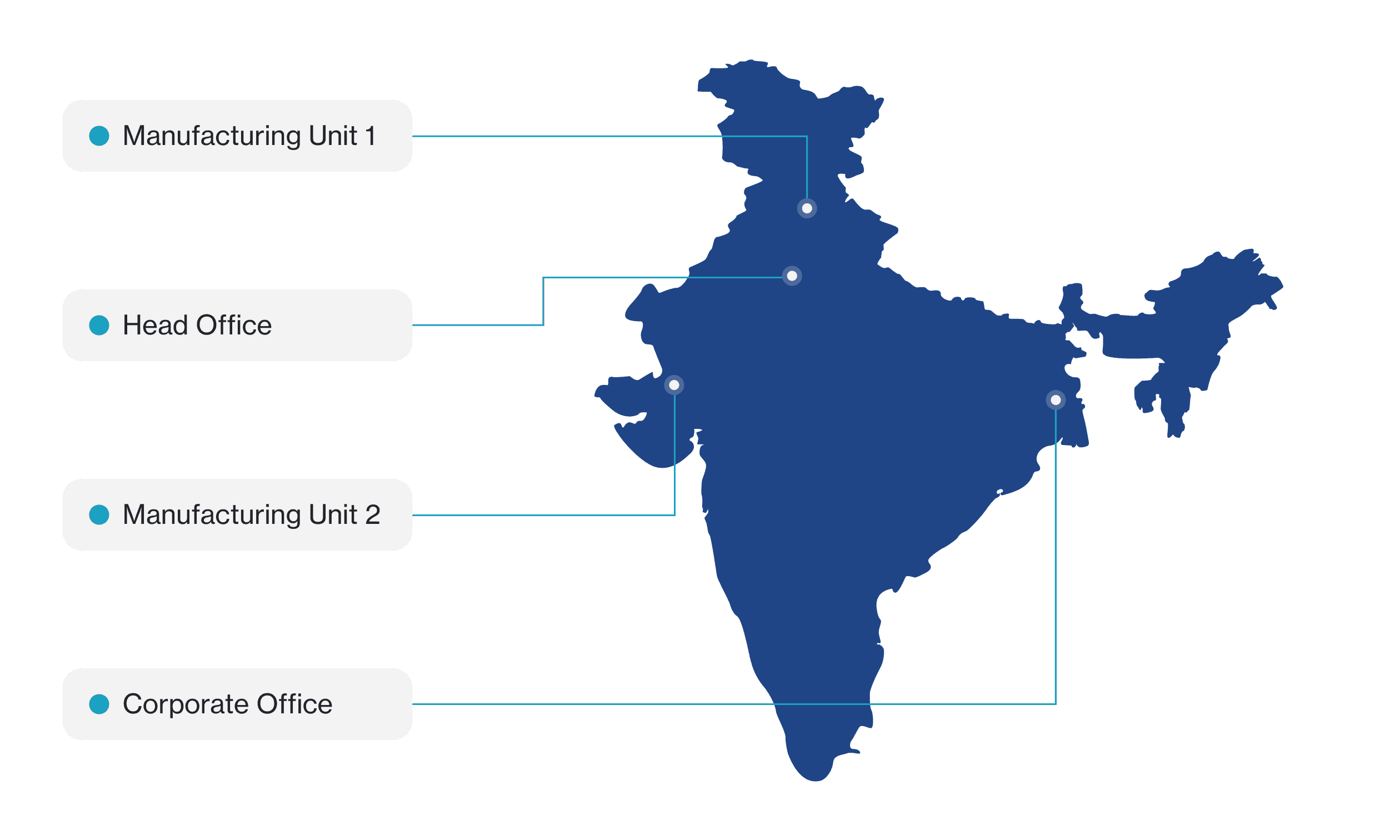

With state-of-the-art factories across India (Noida, Surat, Nalagarh, Sikandrabad), Veeline ensures fast production and distribution. Their products meet ISO-9001 and Energy Star certifications, reflecting international quality standards.

Innovation with Sustainability

From integrating eco-friendly refrigerants, Veeline combines technological innovation with a commitment to sustainability-delivering products that are both powerful and planet-friendly.

At Our Core

Veeline partners with leading brands across India and over 30 global markets, including Saudi Arabia, the UAE, Qatar, Oman, Bahrain, Kenya, Mexico, and Latin America. Our strong regional expertise and global reach reflect a commitment to quality, adaptability, and long-term trust.

We know starting a new career comes with many questions-and we’re here to help. This FAQ section gives you quick, clear answers about our hiring, culture, and benefits.